| (C) 2019 inakakaoubouKANAI |

| Falcon11 Z-WING manipulate Falcon11 Glide test Z-WING manipulate Falcon12 |

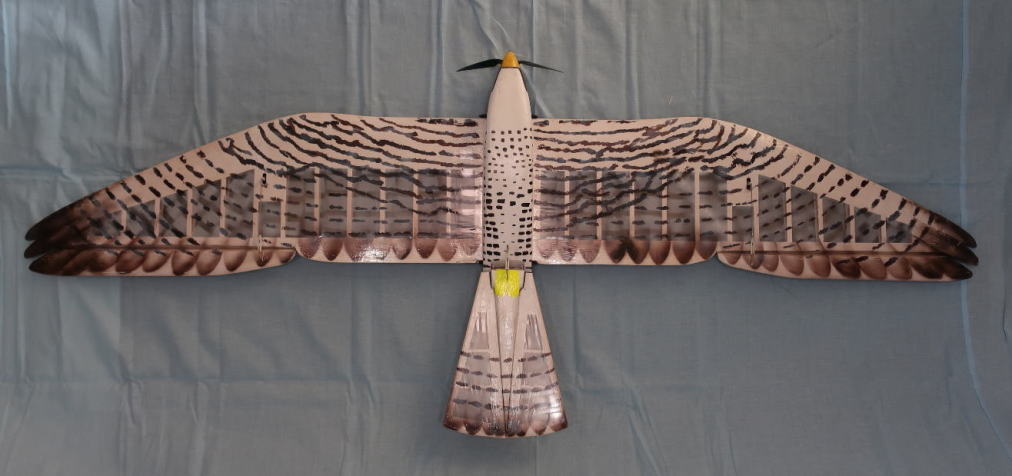

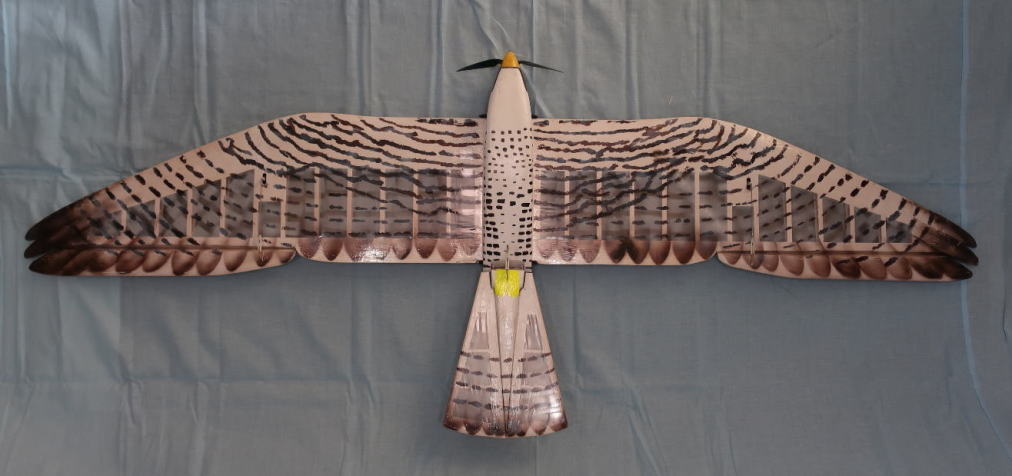

| Falcon11 |

|

|

|

|

| <<< bird |

| Production of the Falcon11 & Falcom12 |

| (C) 2019 inakakaoubouKANAI |

| Falcon11 Z-WING manipulate Falcon11 Glide test Z-WING manipulate Falcon12 |

| Falcon11 |

|

|

|

|

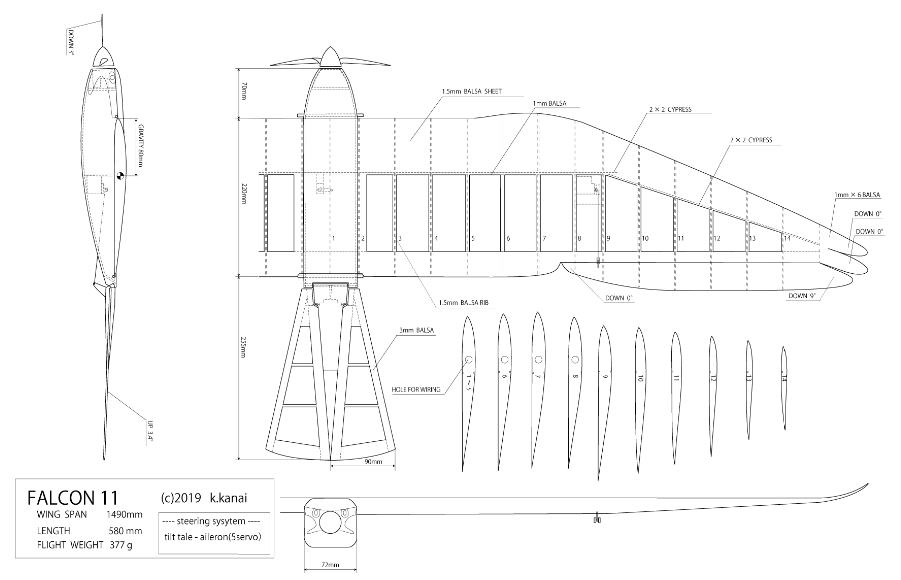

| BLUE PRINT |

| Expansion |

|

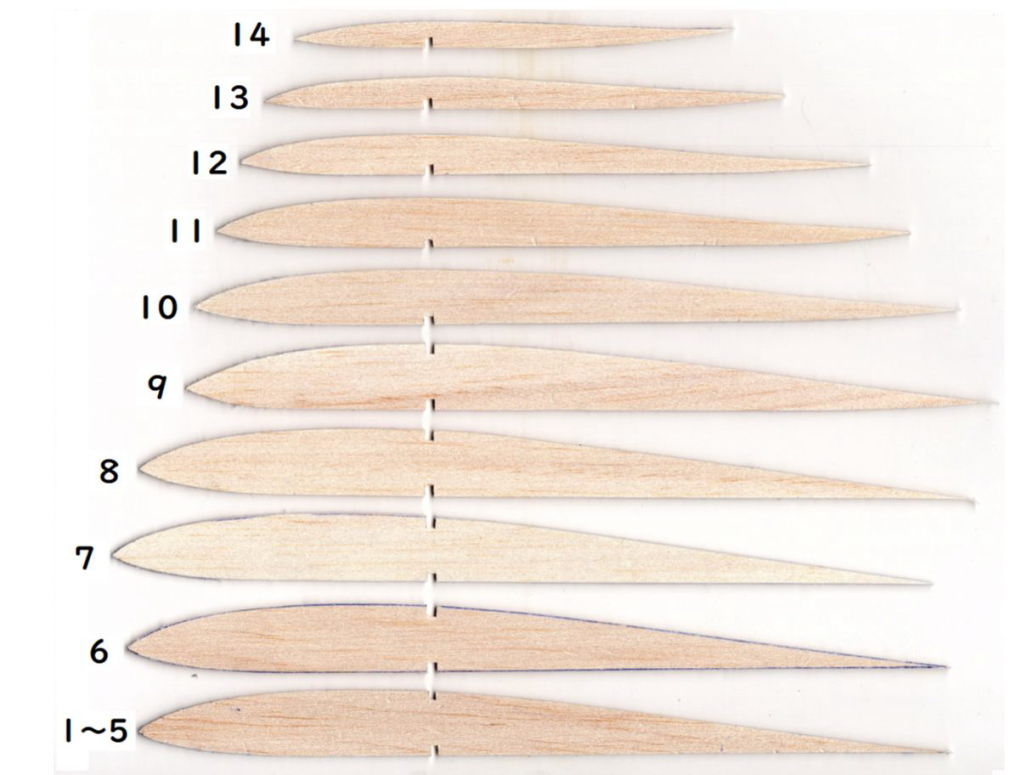

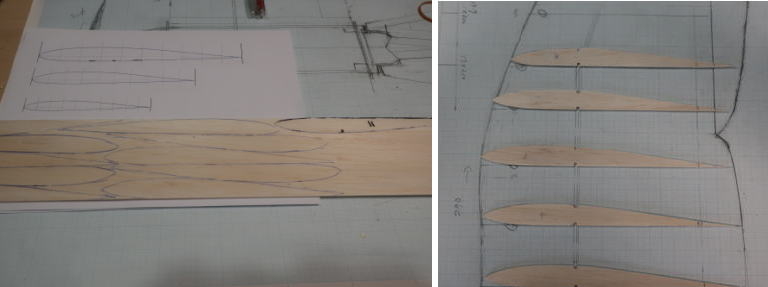

| RIB |

|

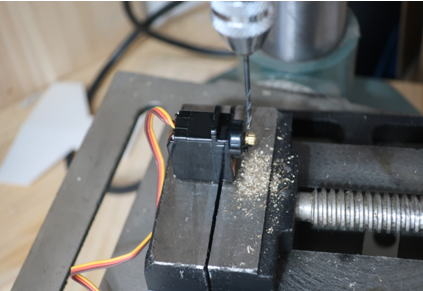

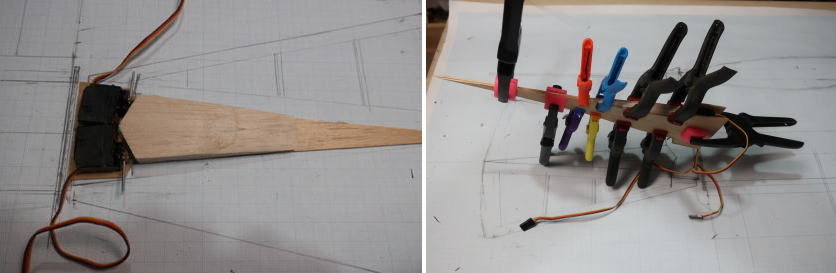

| Tail making |

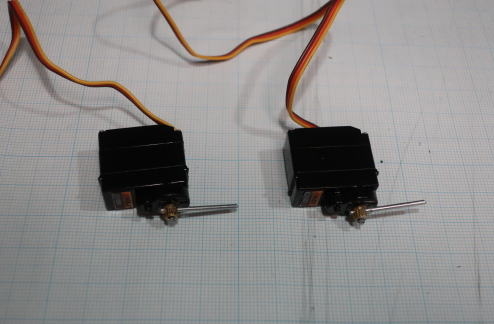

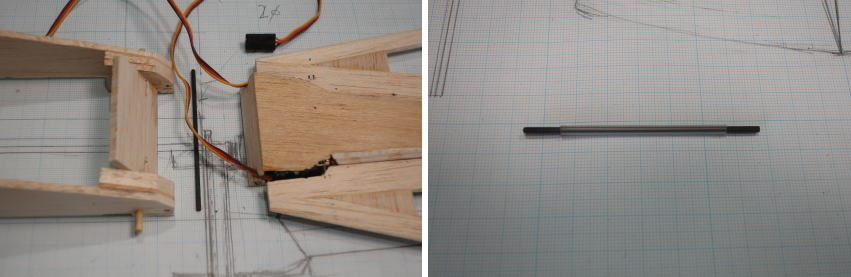

| Drill a hole in the tail servomotor and pass the piano wire. It requires strength and uses a metal geared servomotor. |

|

| Cut off the screw heads. |

|

| Make a tail with four 1.5mm thick balsa boards. |

|

| Glue the servo motor. |

|

|

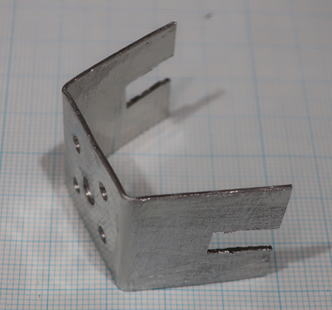

| Making the fuselage |

| Make a mount to attach the motor with 1mm thick aluminum plate. |

|

| Bend the balsa plate to be the side plate with a steam iron. |

|

| Glue the side plate and the motor mount. Align with the torso corner. |

|

|

| Connect the tail and body with a carbon shaft and nylon pipe. |

|

| To increase the strength, glue the glass wool with Titebond. |

|

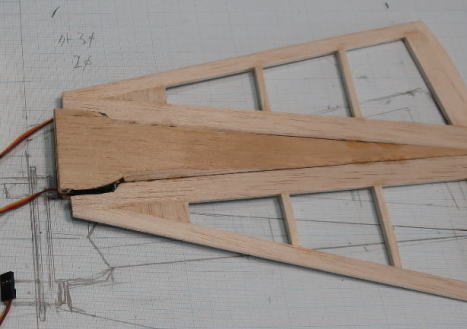

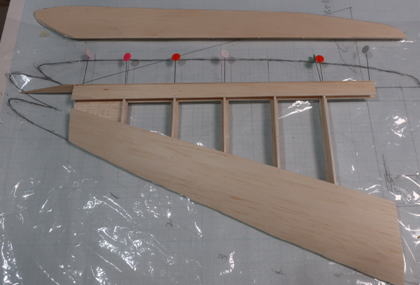

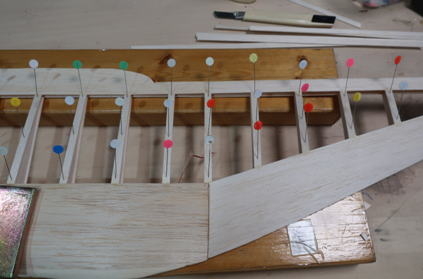

| Wing production |

| Cut out ribs from 1.5mm thick balsa board. |

|

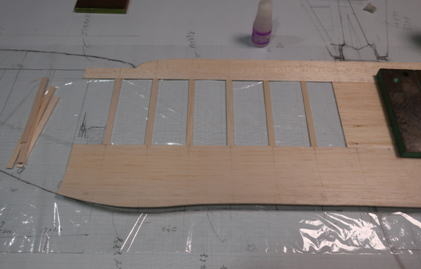

| Place 1.5mm thick balsa on the polyethylene film. Then attach the ribs with instant glue. |

|

|

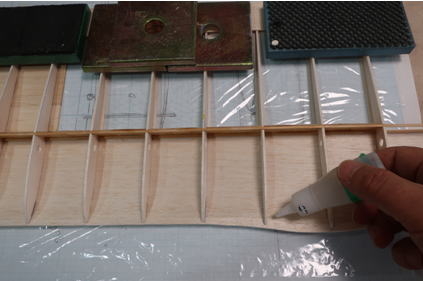

| Glue the rib cap with Titebond. |

|

| Cut out fins from 1.5mm balsa board. |

|

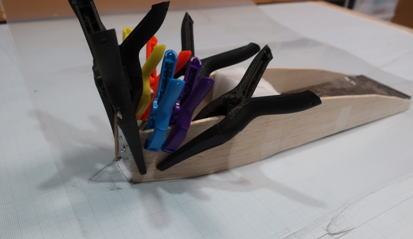

| Apply glue and press with metal fittings. |

|

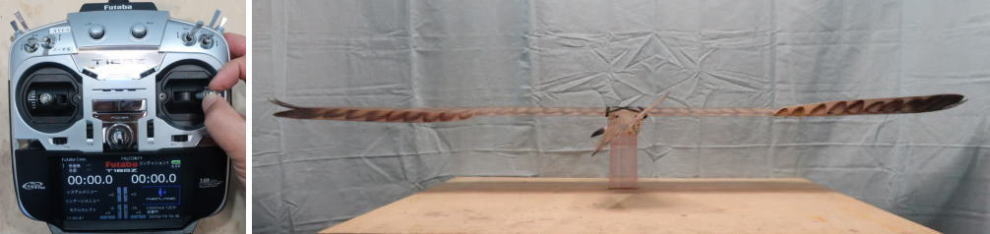

| Assembly |

|

|

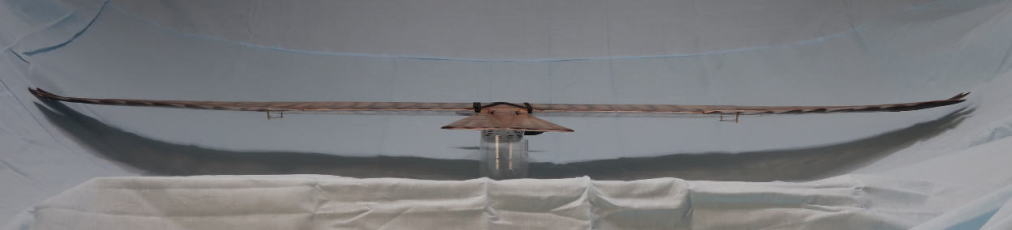

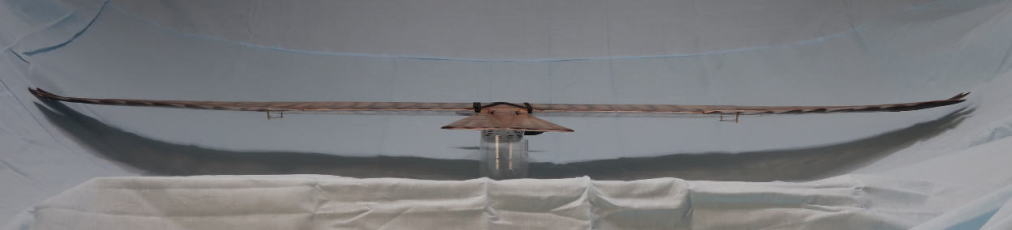

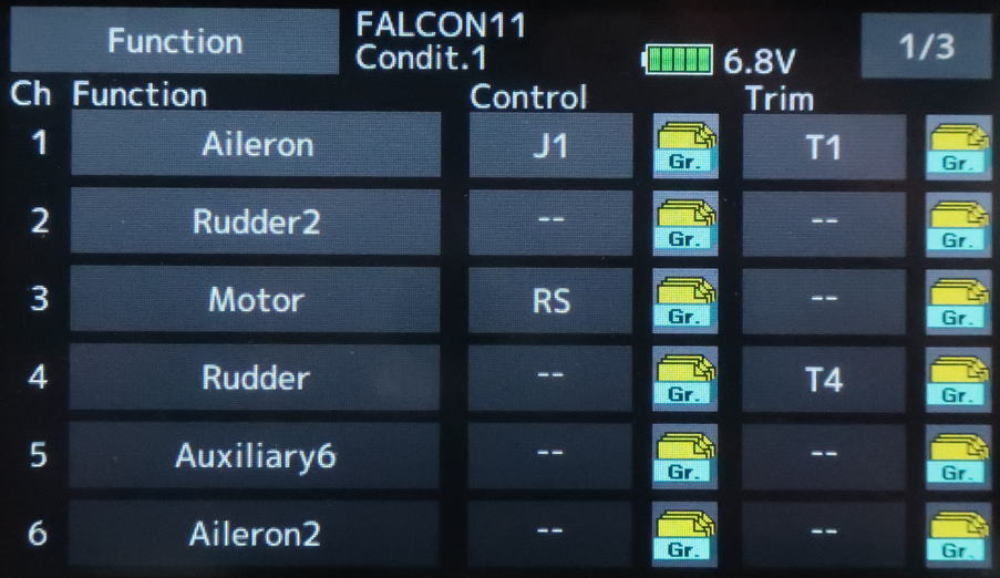

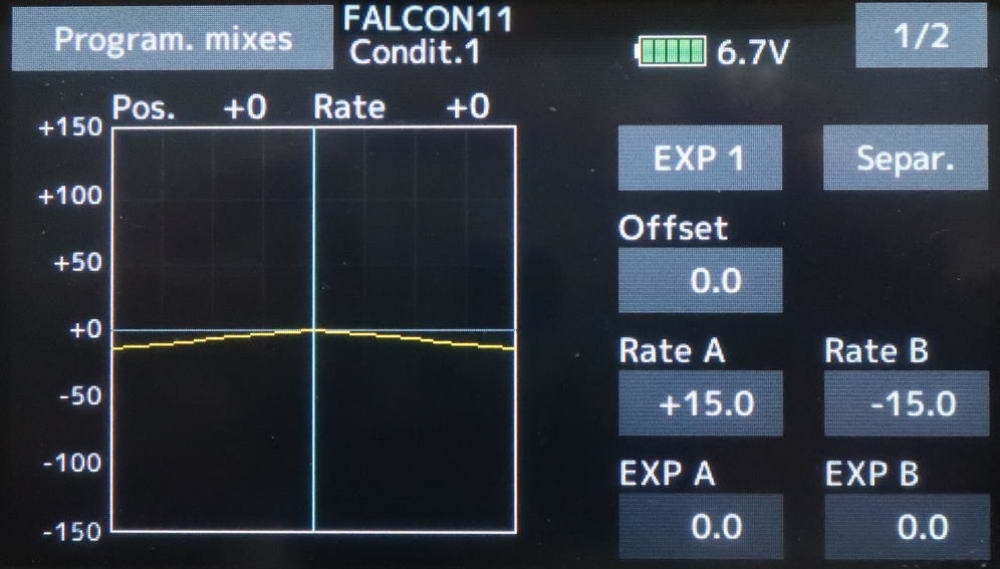

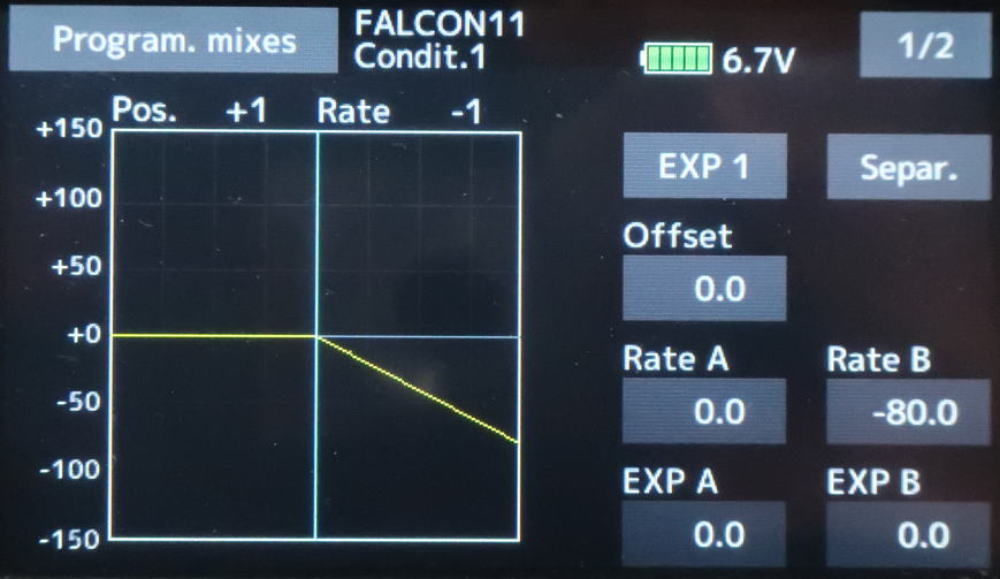

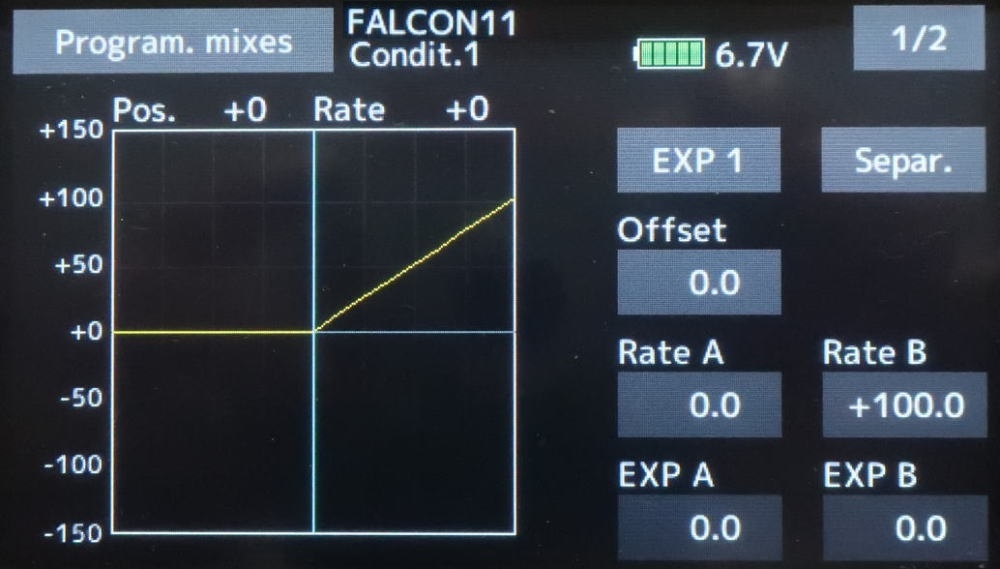

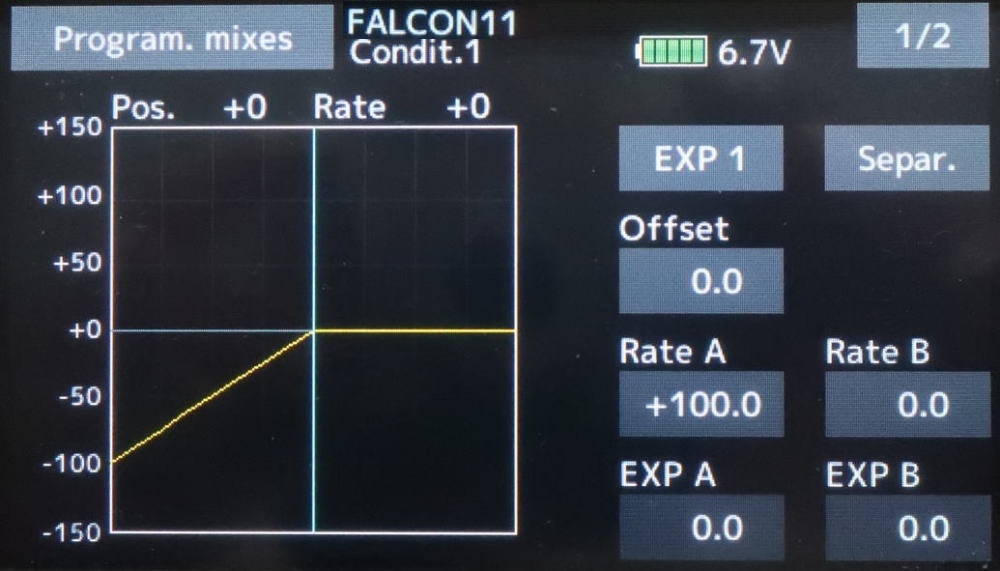

| Z-WING manipulate Falcon11 |

LEFT rudder  |

RIGHT rudder  |

UP  |

DOWN  |

LEFT aileron  |

RIGHT aileron  |

BRAKE  |

RISE when landing  |

|

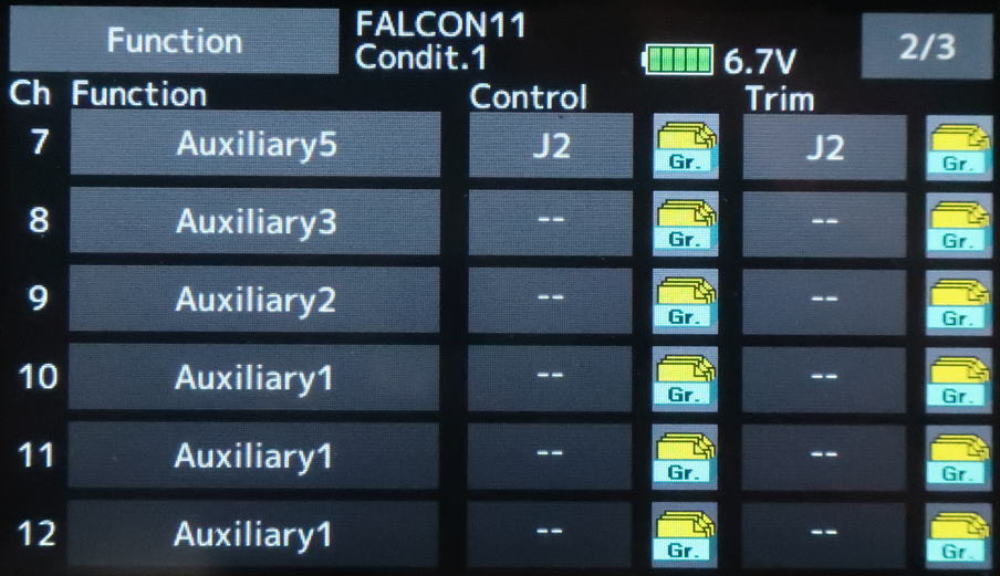

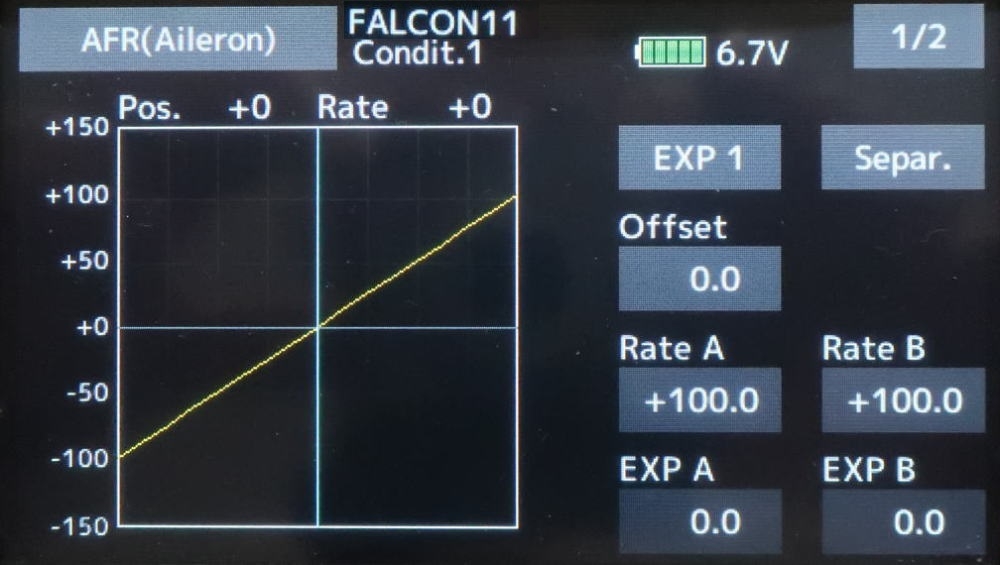

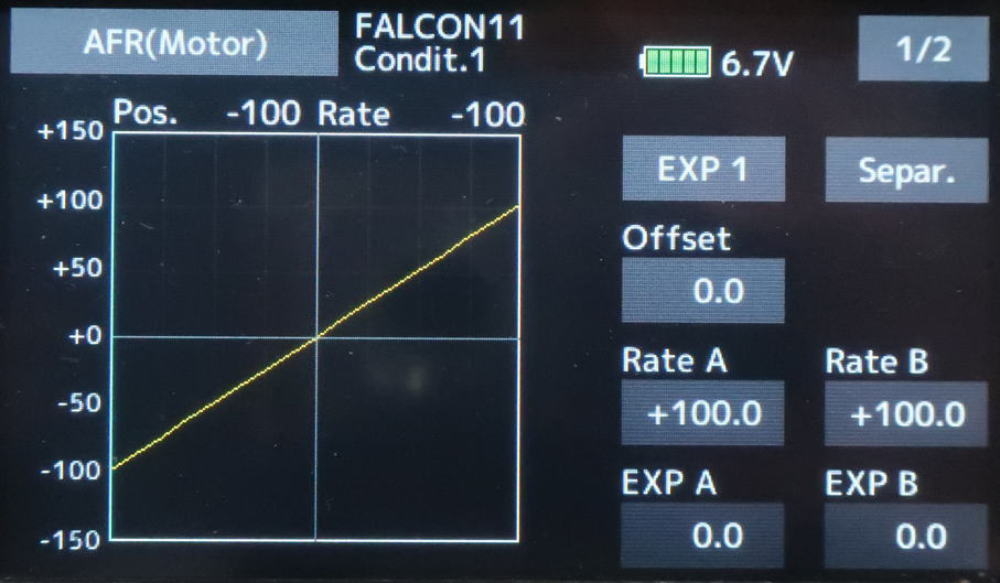

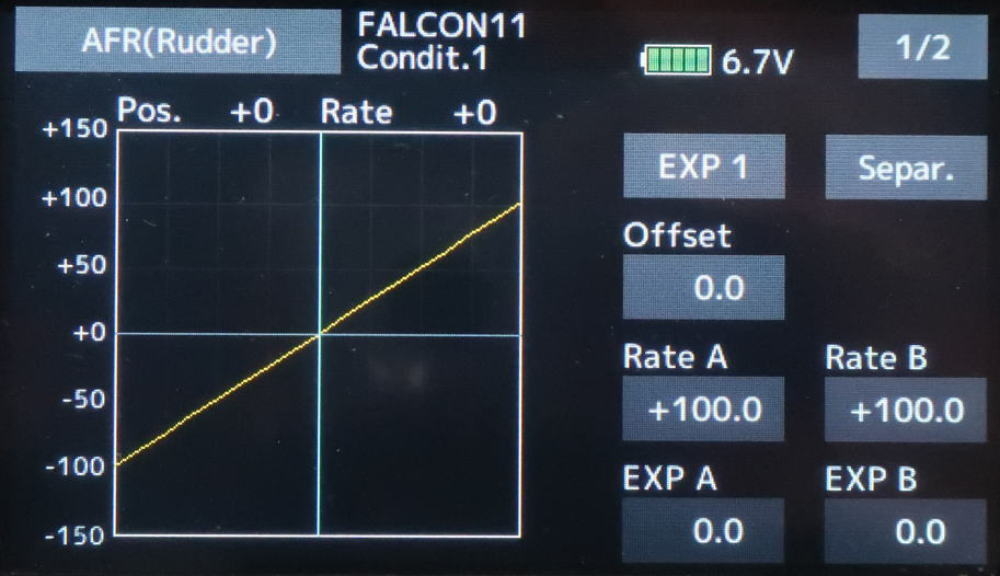

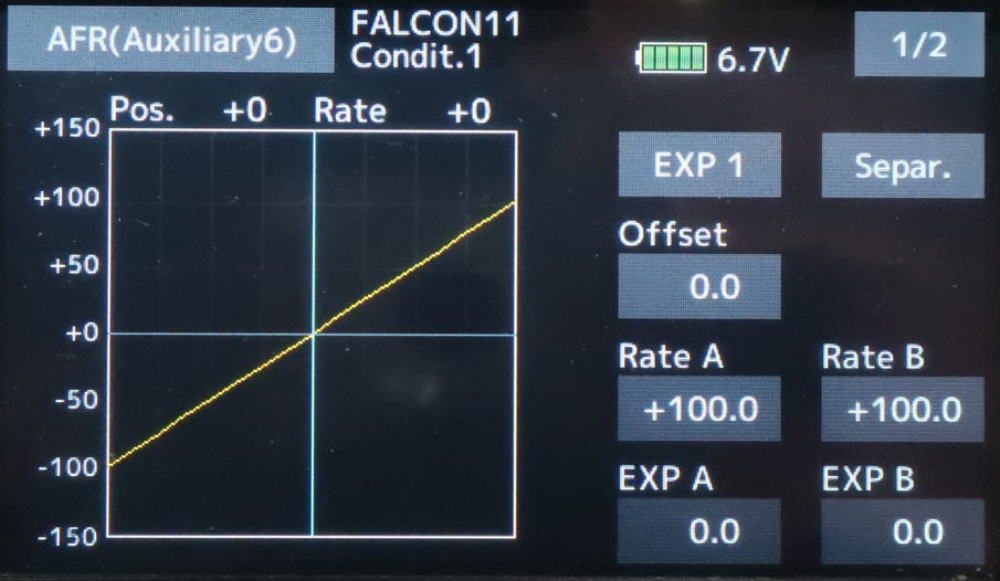

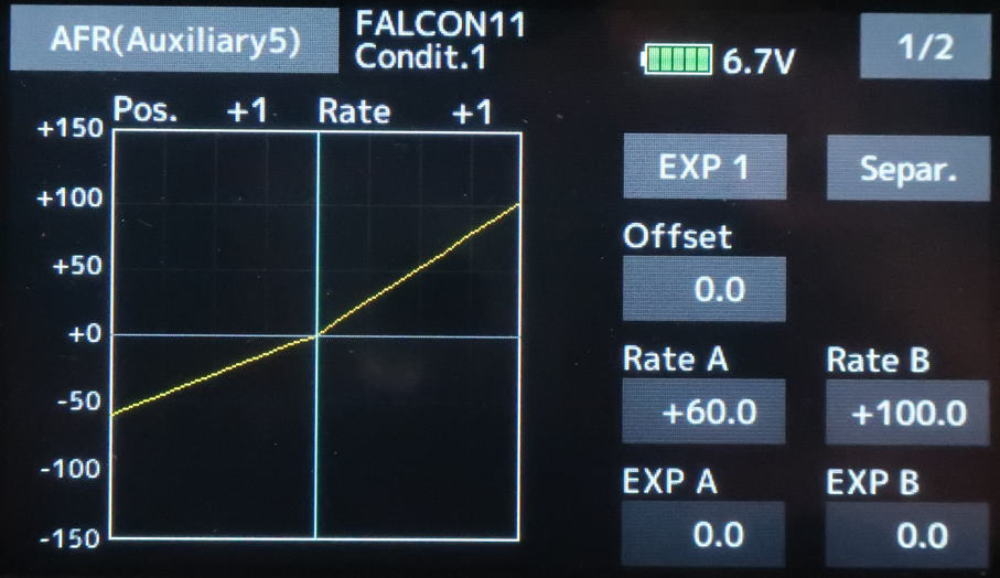

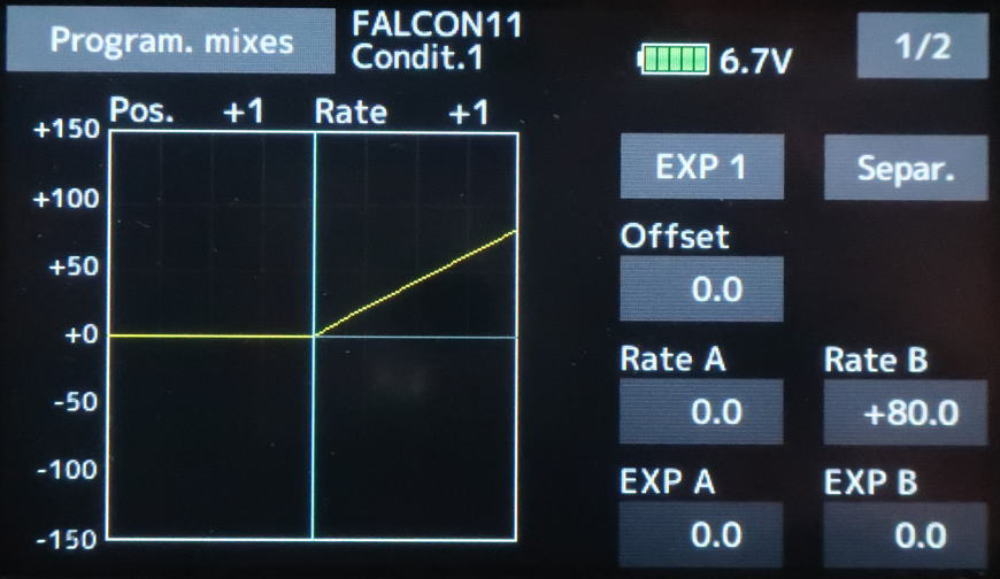

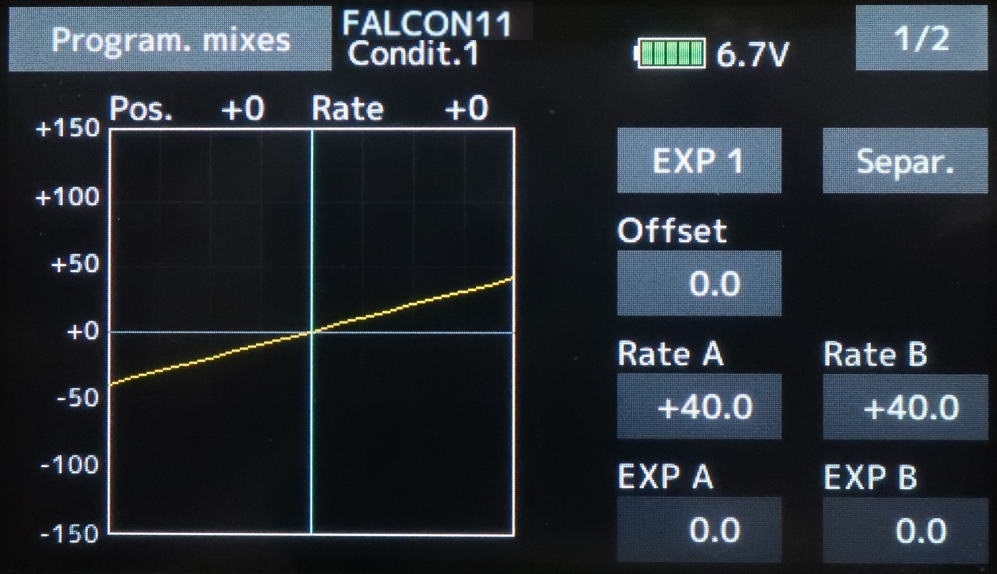

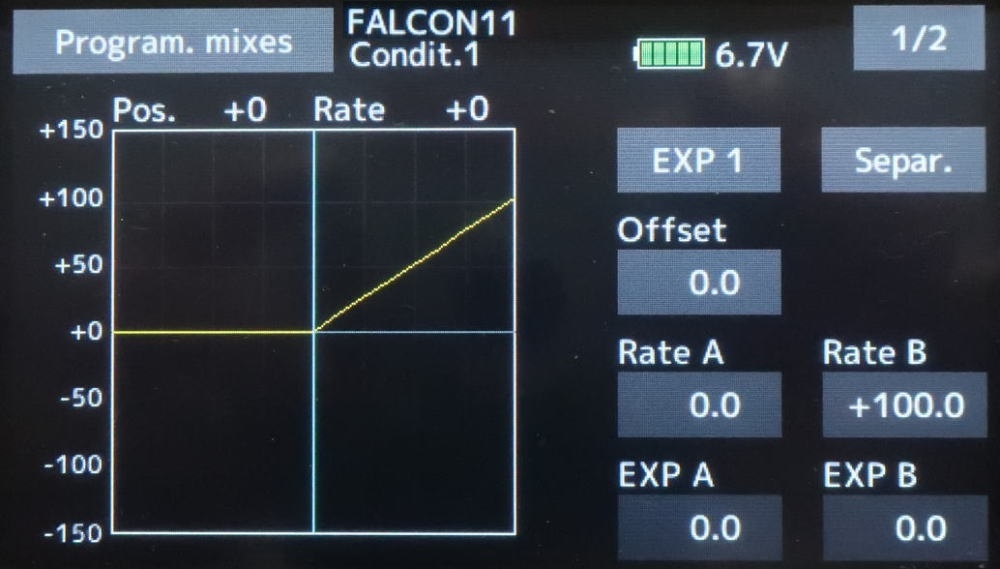

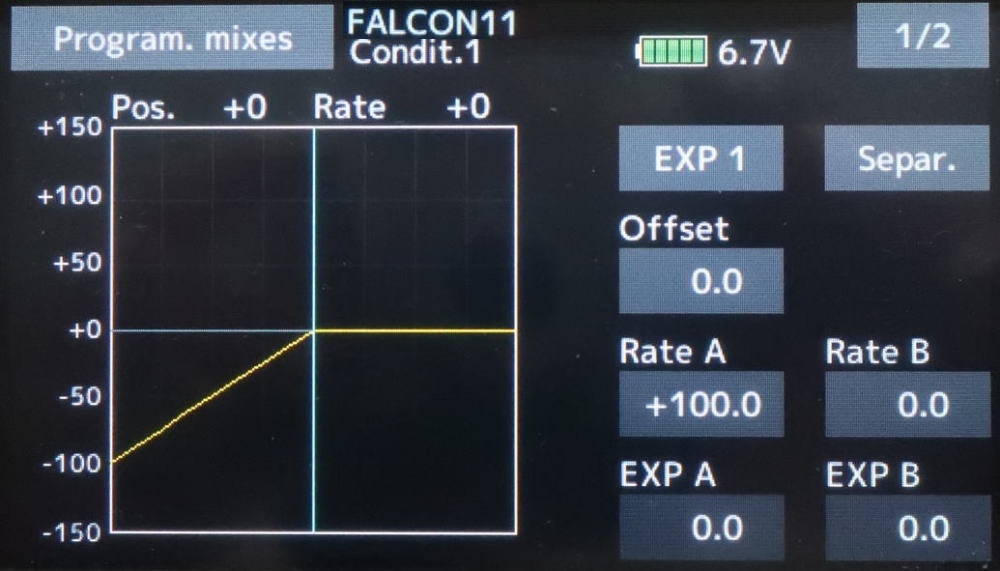

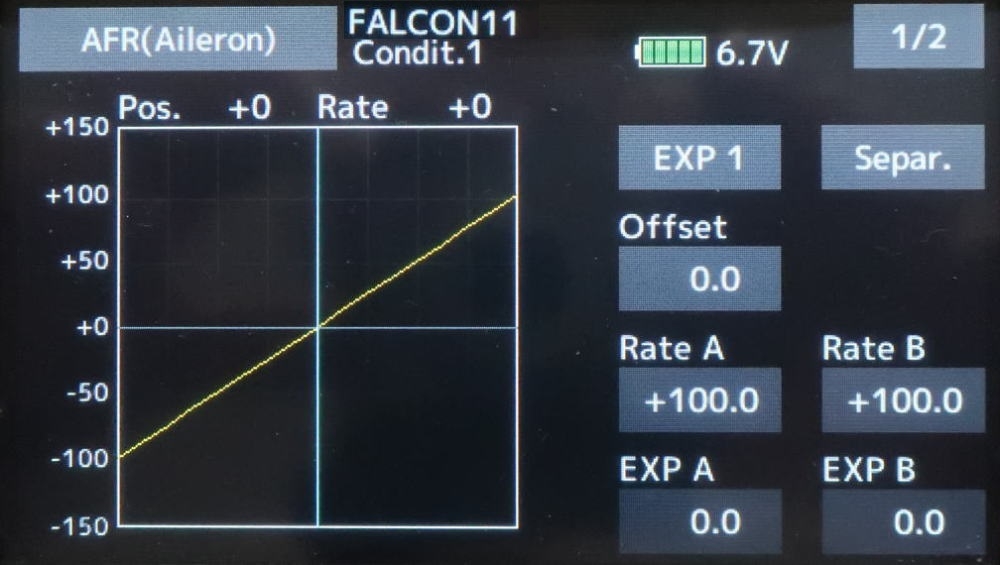

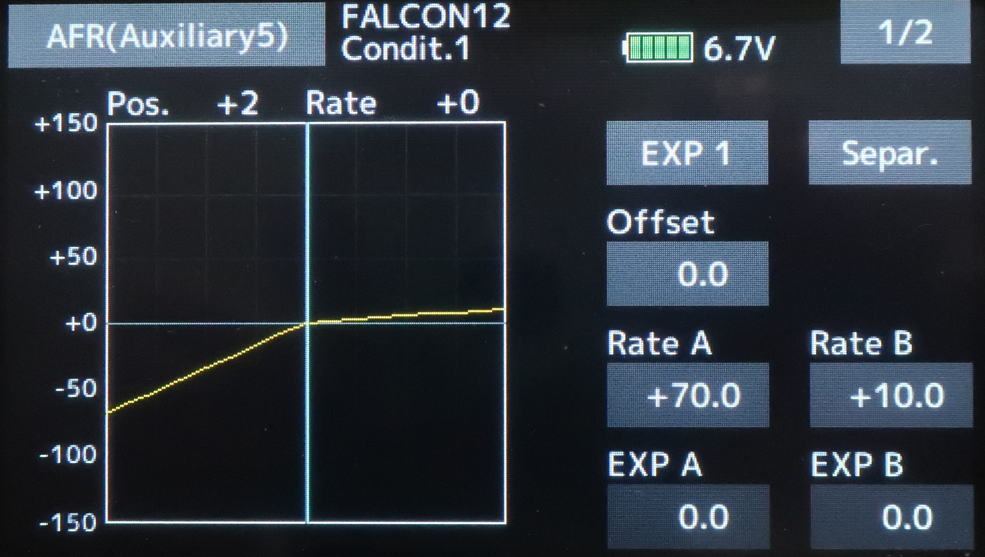

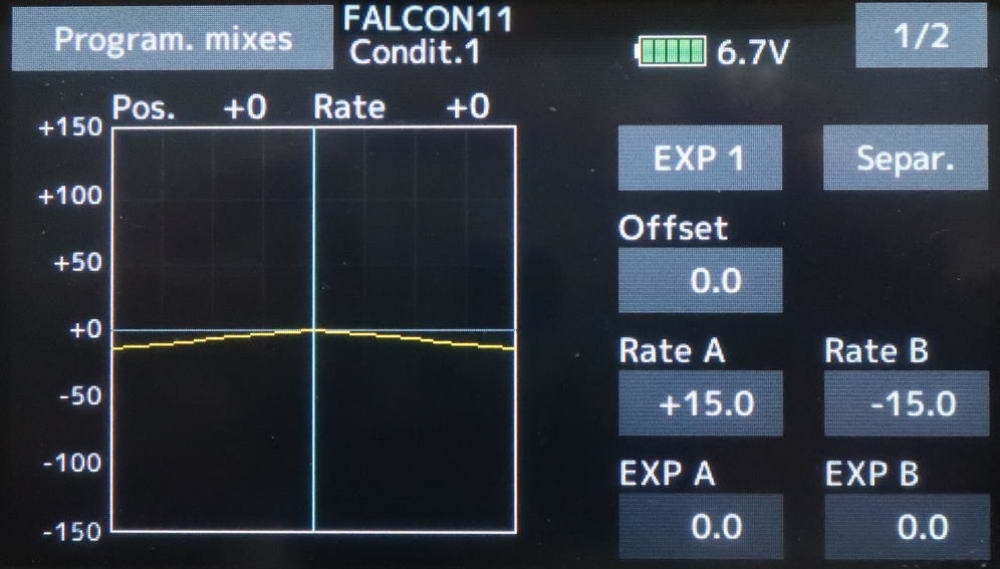

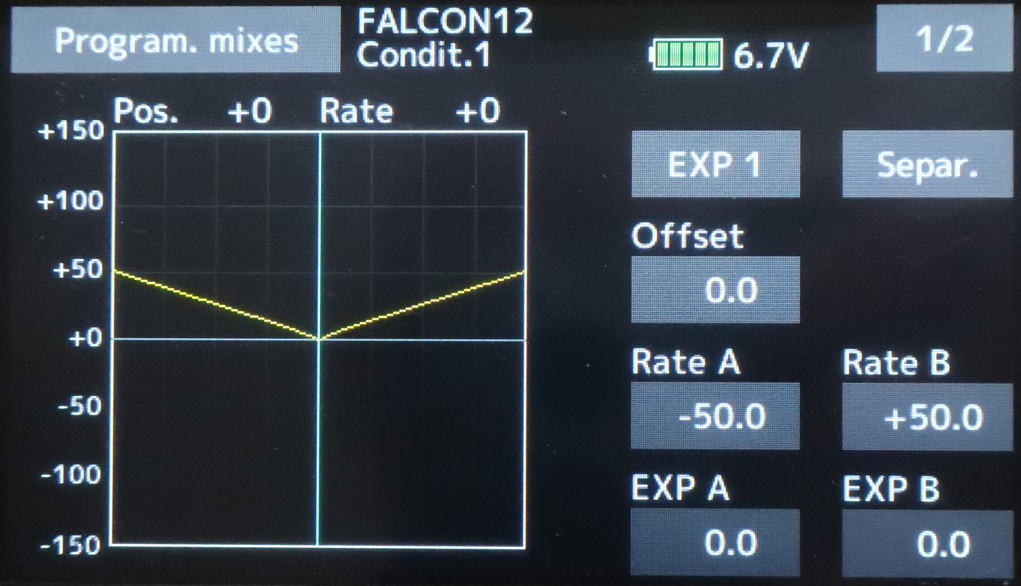

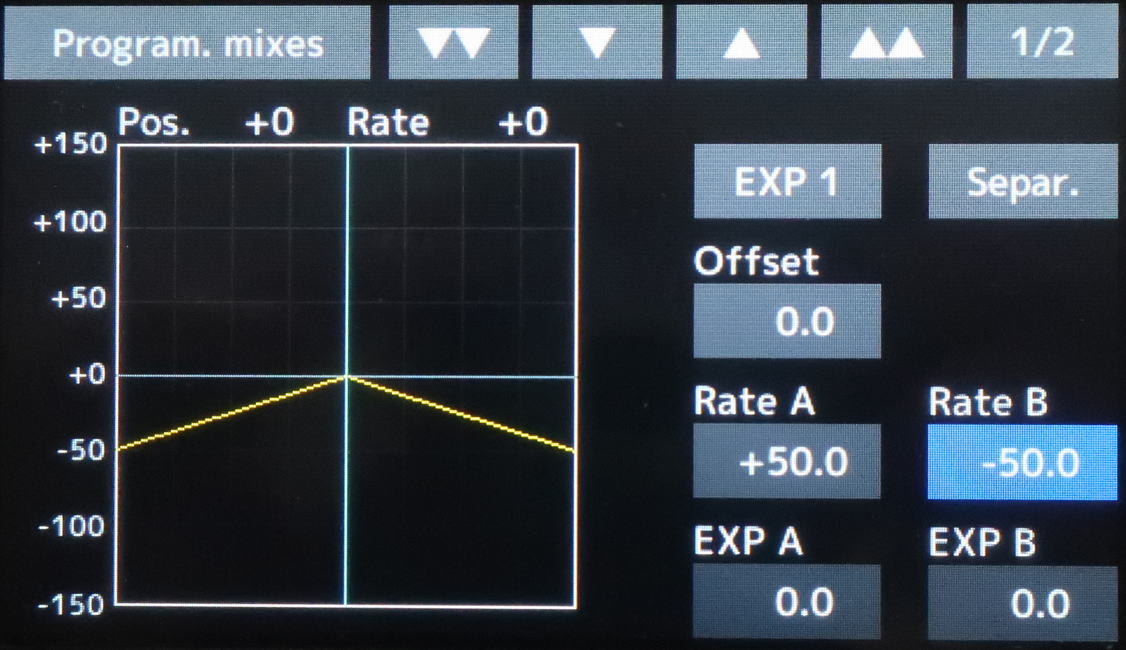

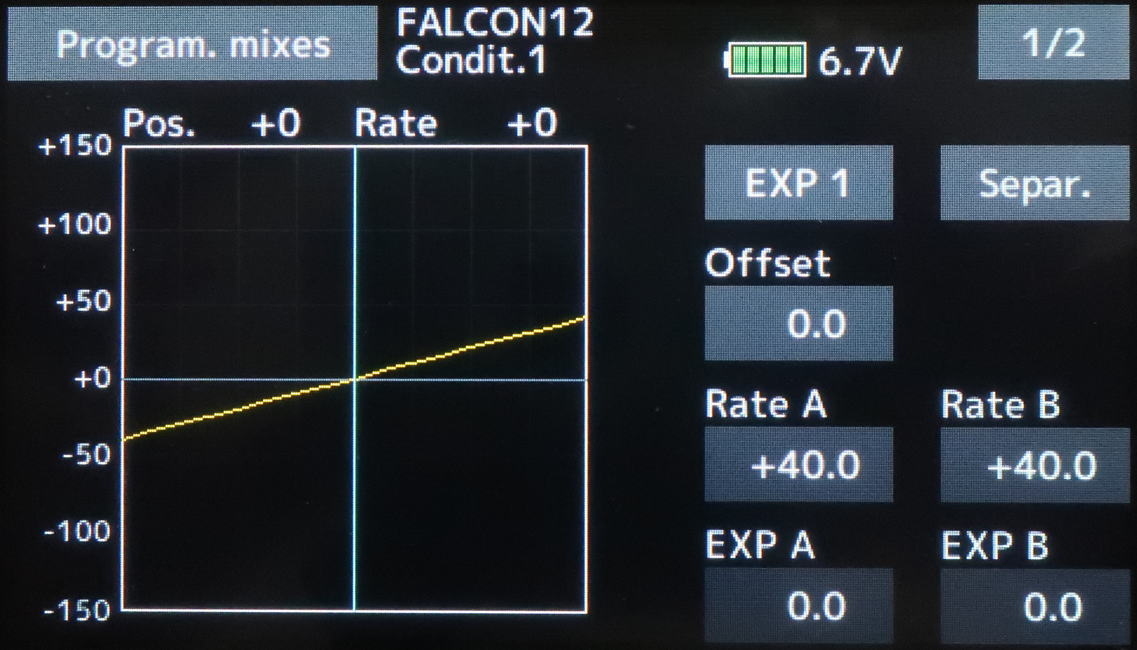

AFR      J1→Auxiliary5 Mixing  J2→Aileron Mixing  J2→Aileron2 Mixing  J3→Auxiliary5 Mixing  J4→Rudder Mixing  J4→Rudder2 Mixing  |

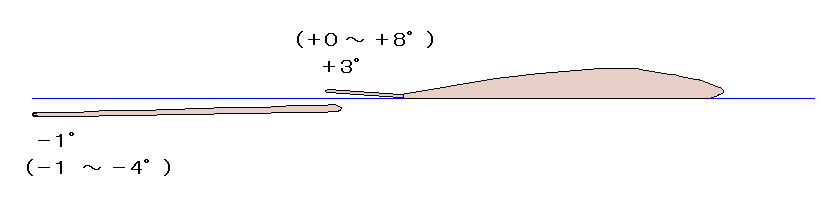

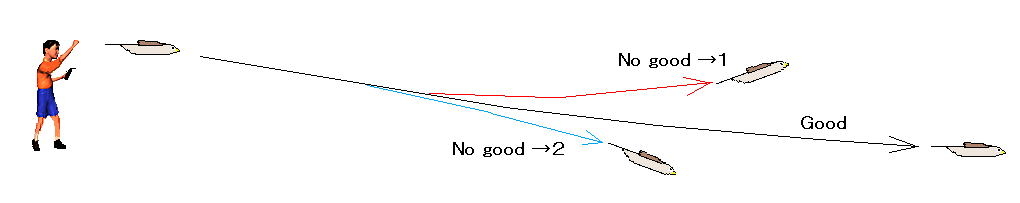

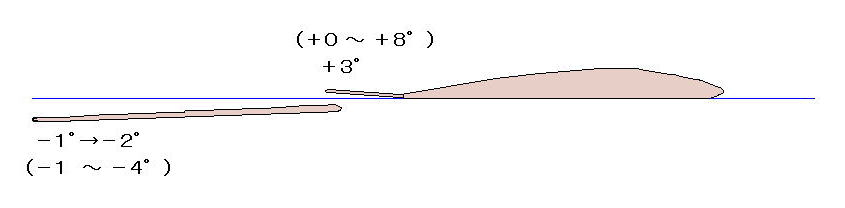

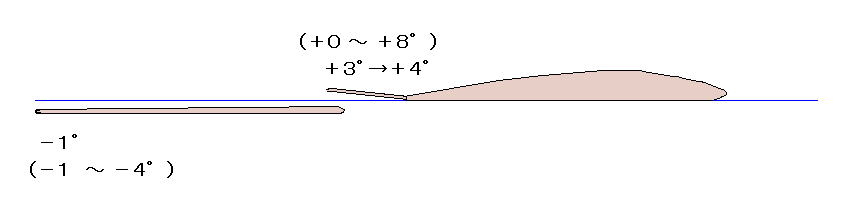

| Glide test | |

The tail should not be raised above the standard.  |

|

| No good→1 | |

|

|

| No good→2 | |

|

|

|

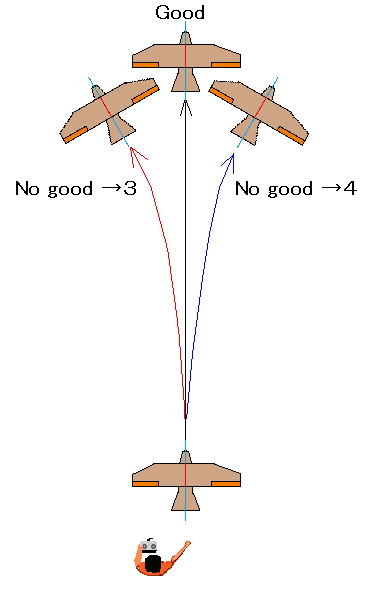

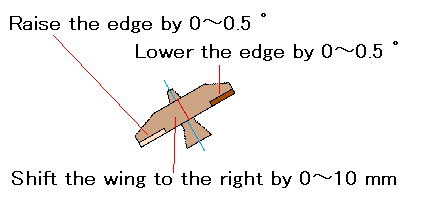

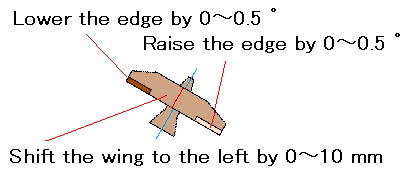

No good →3  Reduce left wing drag No good →4  Reduce right wing drag |

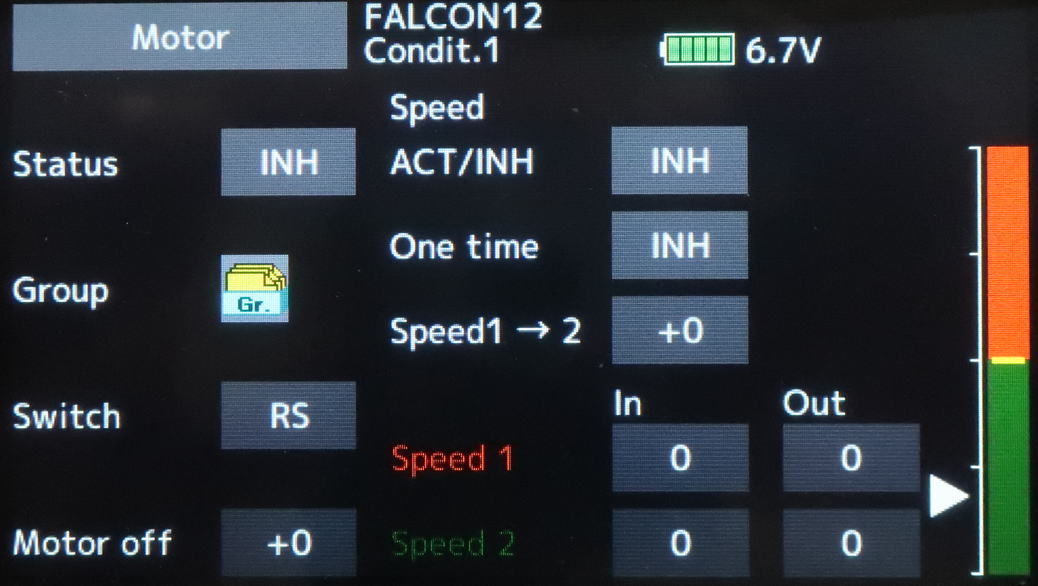

| Falcon12 |

Controlled the nose and improved maneuverability. Controlled the nose and improved maneuverability. |

|

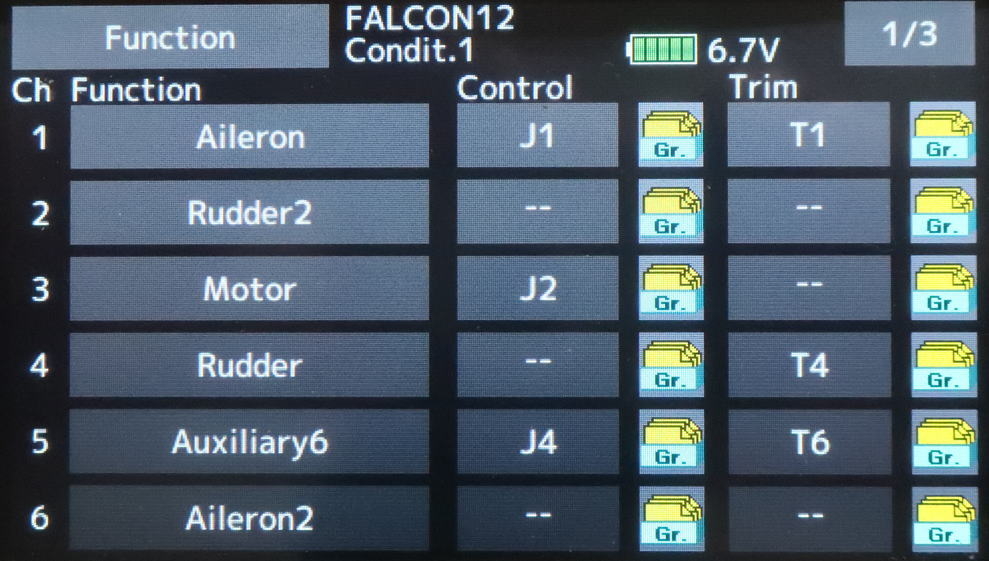

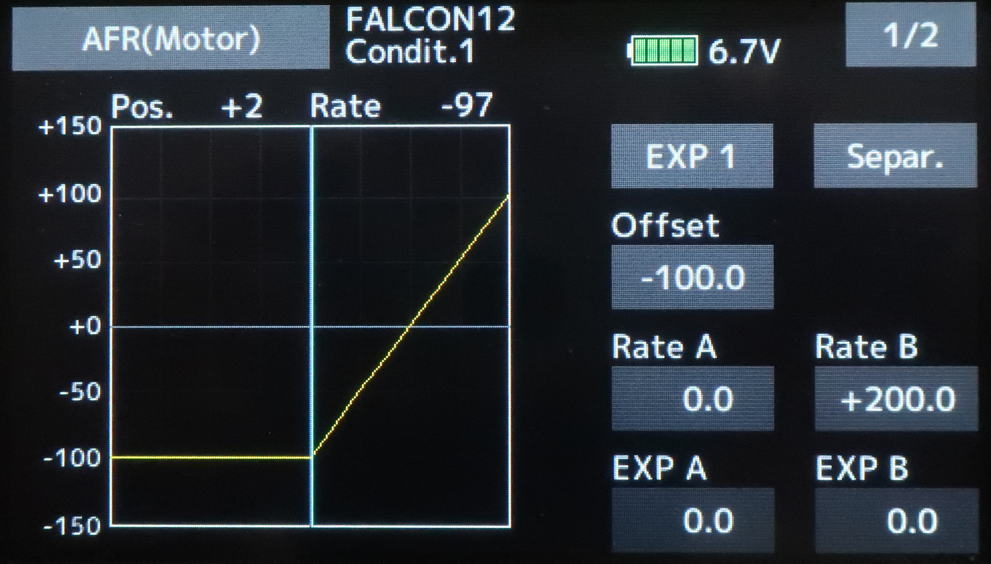

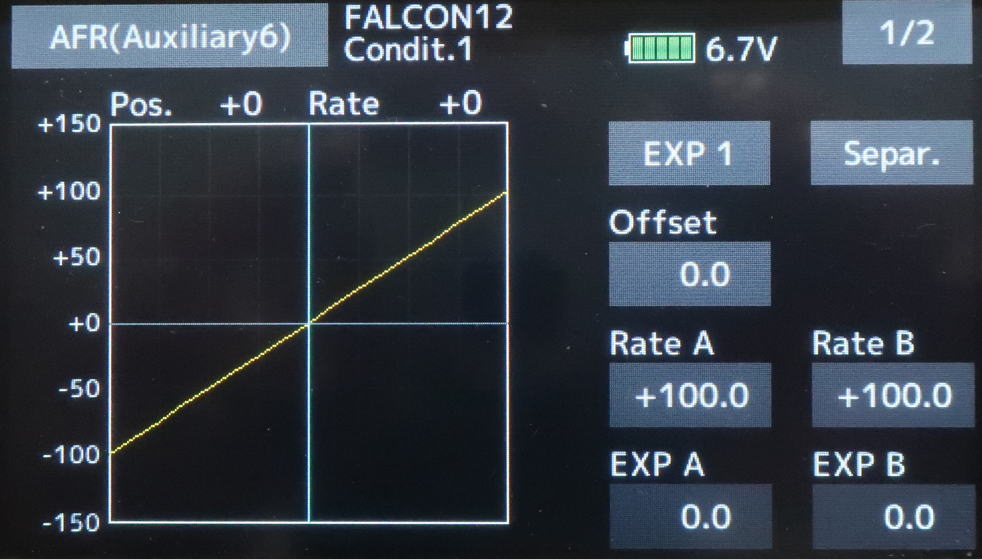

AFR     J1→Auxiliary5 Mixing  J2→Rudder Mixing  J2→Rudder2 Mixing  J3→Auxiliary5 Mixing  J4→Rudder Mixing  J4→Rudder2 Mixing  Motor  |